VECTR Center AI-Enhanced Robotic Manufacturing Studio unveiled

The VECTR Center state of the art facility is a partnership of Central Georgia Technical College, 21st Century Partnership and Georgia AIM.

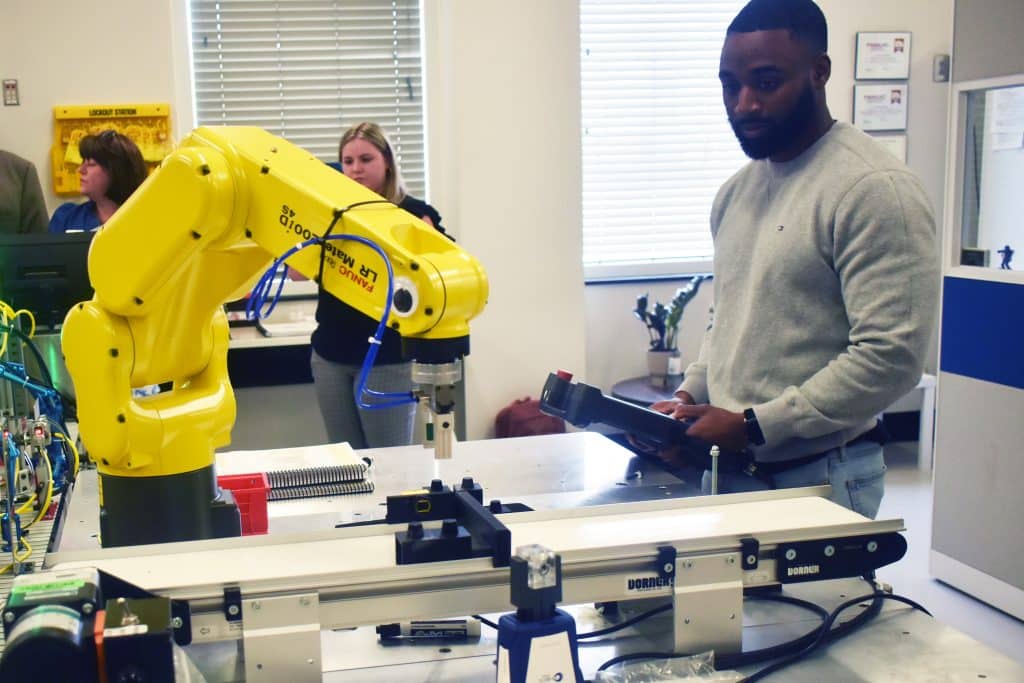

WARNER ROBINS—A partnership between an area college and several organizations created a state-of-the-art robotic facility at the VECTR Center, and the community gathered Wednesday morning to celebrate its accomplishments with a ribbon-cutting ceremony.

Central Georgia Technical College’s AI-Enhanced Robotic Manufacturing Studio boasts industrial and manufacturing technology. Through a hands-on training program, students are prepared for careers in these fields, according to a release by CGTC.

The first round of students began the program in October 2023 and finished the course in February. The program has seen interest among students and employers, enough for another round in the spring semester.

The VECTR Center facility results from a partnership between the college, 21st Century Partnership and Georgia Institute of Technology. Georgia Tech leads a statewide initiative, the Georgia Artificial Intelligence in Manufacturing coalition, which combines innovation in artificial intelligence and manufacturing with transformational outreach and workforce development.

At the ribbon cutting, leaders from these organizations spoke about the role the organizations and technology play in a changing workforce.

CGTC President Dr. Ivan Allen said he enjoys partnerships that lead to projects like the manufacturing studio.

“It’s so cool to get up every day and work with the people I get to work with, and do stuff like this. This is so cool. There’s no pretense to it. We’re just trying to help people and we’re trying to deliver on Georgia’s promises,” he said.

Dr. Aaron Stebner, co-director for Georgia AIM and professor of mechanical engineering, materials science and technology at Georgia Tech, also spoke on collaboration with CGTC and 21CP. He further explained Georgia AIM’s goal to ensure citizens of all backgrounds can find a fulfilling technological career amid an evolving technological landscape.

He also credited CGTC for its swift response to regional business needs, combining valuable education in a quicker program. According to Stebner, the course’s curriculum was approved at the state level in eight months.

“I have tried to get one course in machine learning for engineers through Georgia Tech’s approval process, and it’s taken me more than three years. [That gives] you a sense of how remarkable that is in state education and that also speaks to the community college system, Technical College System of Georgia and their ability to be agile, to respond to localities needs, and really make a difference and impact both their community and their economies,” he said.

Brig. Gen. John Kubinec, 21CP President/CEO, said the robotics studio shows their efforts and partnership with CGTC and Georgia AIM. He said 21CP’s goals are increasing efforts for STEM education among children, citing programs like Middle Georgia STEM Alliance and a mobile STEM lab with Fort Valley State University.

He also mentioned an increased role in technology at Robins Air Force Base, saying robotics still requires a trained eye. He emphasized that robotics is not a way to replace skilled labor but to take those trained out of dangerous conditions.

“I’d much rather have a painter operate the robot that’s painting, because they know what right looks like, then just have a robotics operator that’s never painted. So, how do we take those technicians, that are great at what they do, and train them to be able to operate the robot to do that, where they still have that skilled eye to know what right looks like? Well, this is how we do it: with what we’re here to celebrate today,” Kubinec said.

Finally, Deryk Stoops, an instructor in CGTC’s AI-Enhanced Robotic Manufacturing program, discussed the details of the program and the manufacturing industry in general.

He also said manufacturing is a field that takes raw materials and adds value to them, benefiting the community.

Stoops said the program’s students learn various topics, such as introductions to AI and manufacturing, industrial safety, basic electrical and hydraulic power, machine vision and programming.

“They get all that in about 15 weeks and they leave, in my view, very valuable, to certainly go out and have the job skills to go and start working. Not just working, but really helping our manufacturing environment, as new manufacturers come along, as our incumbent manufacturers here in middle Georgia start ramping up their adoption of technology. I think we’re really helping prepare students that are going to be great workers,” he said.

More information about the AI-Enhanced Robotic Manufacturing program can be found here.

Before you go...

Thanks for reading The Houston Home Journal — we hope this article added to your day.

For over 150 years, Houston Home Journal has been the newspaper of record for Perry, Warner Robins and Centerville. We're excited to expand our online news coverage, while maintaining our twice-weekly print newspaper.

If you like what you see, please consider becoming a member of The Houston Home Journal. We're all in this together, working for a better Warner Robins, Perry and Centerville, and we appreciate and need your support.

Please join the readers like you who help make community journalism possible by joining The Houston Home Journal. Thank you.

- Brieanna Smith, Houston Home Journal managing editor