Testing… testing…: Robins First Article Test Lab ensures parts make the grade

From concept to construction, aircraft parts undergo a thorough process to ensure they are ready for the fight, including a stop at the First Article Test Lab.

ROBINS AIR FORCE BASE — From concept to construction, aircraft parts undergo a thorough process to ensure they are ready for the fight. And on Robins Air Force Base, the First Article Test Lab does what its namesake suggests: testing.

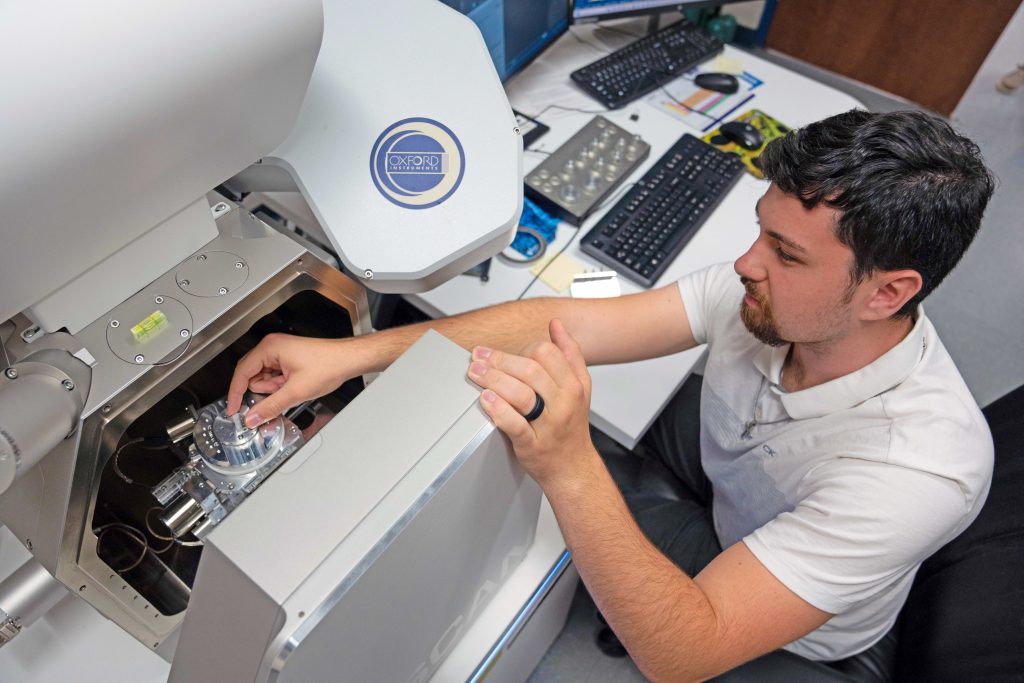

As explained by First Article Test Team lead Jeffrey Hunter, first articles, parts that a contractor has not made in the last three years or made through the Department of Defense’s logistics agency, are under the metaphorical — and sometimes literal microscope.

Once a first article arrives at the lab, the team gets to work, verifying dimensions, materials, coatings, electrical work, fit, and functionality. Hunter said the most common parts will go to the C-130, F-15, and C-5 weapons systems, but the team also inspects “one-off” components from the Commodities Maintenance Group and the Aircraft Maintenance Group.

The specifications, like materials and dimensions, are outlined in drawings, Hunter explained. From the drawing, an engineer will create a test plan and send it to the lab.

“From there, we verify that part meets those specifications that they called out or highlighted on the drawing, and then we’ll develop a report of our findings, and then we give that report to the project engineer, let them review it, and they make a determination if the part’s acceptable or unacceptable,” Hunter said.

Several groups may inspect a first article. Metrology is responsible for examining measurements and dimensions using coordinate measuring machines, 3D scanners, comparators, image measurement systems, and tube inspection equipment.

Materials testing uses microscopes, hardness testers, environmental chambers and tensile testers. Inorganic and organic testing uses a variety of spectroscopy machines.

Engineering utilizes environmental chambers, vibration tables, explosive atmosphere chambers, and static/dynamic load frames. Electrical testing is conducted with multimeters, oscilloscopes and vector network analyzers.

Most individuals working in the lab have extensive knowledge in engineering or chemistry. The lab also utilizes engineering technicians and a machinist to cut aircraft parts.

The project engineer will write an engineering evaluation letter detailing their finding, which then goes to the logistics agency. The logistics agency then makes the final determination whether a part passes inspection, Hunter said.

The team inspects between 500 and 700 unique first articles each year.

“They can either approve the part, which means it fully passed all the inspections that we tested for,” Hunter said. “They can conditionally approve it, which means it met all the specifications, but there are a few minor discrepancies that can be corrected, but it’s not going to prevent the contractor from manufacturing the part to fulfill the rest of the contract.”

The worst-case scenario requires a complete remake of the part and more testing from the lab.

“[If] they reject it, [that] means we found significant things wrong with the part. It’s going to require the contractor to reproduce the part and send in a first article for us to verify that it’s correct,” Hunter said.

He said discrepancies are mainly caused by the manufacturer using an outdated blueprint, which can lead to potential incompatibility with current systems. Other discrepancies involve parts made of the wrong material, such as aluminum that wasn’t appropriately heat-treated, potentially leading to a weaker part.

In all they do, the team is a crucial line of defense to ensure parts are up to the challenge.

“[Airmen] can have confidence that part is going to work as intended. It’s made from the right material, not going to fail,” Hunter said. “Our role is important, because we’re giving confirmation to the war fighter. They can trust the part they’re getting is going to be correct.”

Before you go...

Thanks for reading The Houston Home Journal — we hope this article added to your day.

For over 150 years, Houston Home Journal has been the newspaper of record for Perry, Warner Robins and Centerville. We're excited to expand our online news coverage, while maintaining our twice-weekly print newspaper.

If you like what you see, please consider becoming a member of The Houston Home Journal. We're all in this together, working for a better Warner Robins, Perry and Centerville, and we appreciate and need your support.

Please join the readers like you who help make community journalism possible by joining The Houston Home Journal. Thank you.

- Brieanna Smith, Houston Home Journal managing editor